Gloss finish wraps, crafted from high-quality thin vinyl, are a popular choice for both personal and commercial applications due to their stunning aesthetics and durability. Widely used in automotive detailing, these wraps protect vehicle exteriors from scratches and chips, enhancing their appearance. In advertising, they enable businesses to display vibrant designs and logos on fleet vehicles. With permanent adhesion, gloss finishes offer long-lasting protection but cannot be easily removed or corrected, emphasizing the importance of proper surface preparation and high-quality applications for optimal results.

Are you wondering if gloss finish wraps are a permanent or reversible solution? This comprehensive guide explores the ins and outs of these eye-catching materials. We delve into the different types of gloss finish wraps, their applications, and the science behind their adhesion. Learn about the key differences between permanent and reversible options to make informed decisions for your projects. Discover practical tips for successfully working with these versatile wraps.

- Understanding Gloss Finish Wraps: Materials and Applications

- The Nature of Gloss Finish: Permanent vs. Reversible Adhesion

- Practical Considerations: Tips for Working with Gloss Finish Wraps

Understanding Gloss Finish Wraps: Materials and Applications

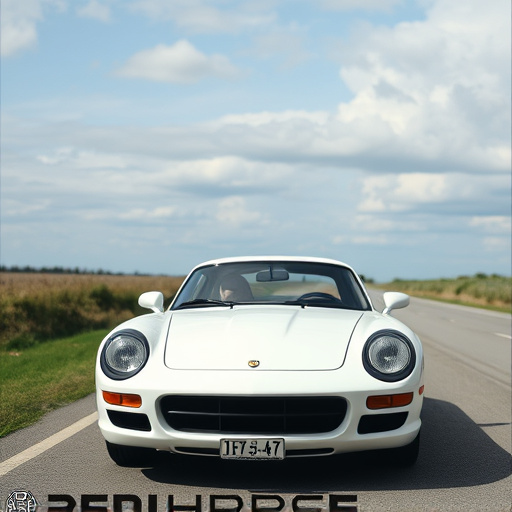

Gloss finish wraps are a popular choice for both personal and commercial applications due to their stunning aesthetic appeal and durability. These wraps are typically made from high-quality, thin vinyl materials designed to adhere tightly to various surfaces, offering an elegant and protective layer. The ‘gloss’ in their name refers to the smooth, reflective surface they possess, making them a top pick for automotive detailing and vehicle protection.

In the world of automotive detailing, gloss finish wraps serve as an effective paint protection film, safeguarding vehicle exteriors from scratches, chips, and other forms of damage. They are commonly used on cars, motorcycles, and even boats to maintain the original look and enhance the overall aesthetics. Beyond their practical benefits, these wraps also find application in advertising and branding, allowing businesses to customize and personalize their fleet vehicles with vibrant designs and logos.

The Nature of Gloss Finish: Permanent vs. Reversible Adhesion

Gloss finish wraps are a popular choice for automotive styling, offering a sleek and modern look. However, understanding the nature of their adhesion is crucial when considering whether they are reversible or permanent. The gloss finish itself refers to the smooth, glossy surface achieved through specialized coatings and polishes, giving vehicles a high-end aesthetic. When applied to windows or other surfaces, these wraps utilize an adhesive backing that secures them in place.

The key distinction lies in the type of adhesion: permanent vs. reversible. Many gloss finish wraps are designed with a strong, permanent adhesive that ensures the wrap stays put even under various environmental conditions. This makes them ideal for long-lasting protection against scratches and stains. On the other hand, some manufacturers offer reversible or removable gloss finishes, suitable for those who wish to change their vehicle’s look periodically without causing damage to the original surface. This is particularly relevant in the context of professional PPF (Paint Protection Film) installations, where a reversible wrap might be preferred for easy removal and replacement at a later date, similar to the concept of ceramic window tinting.

Practical Considerations: Tips for Working with Gloss Finish Wraps

When working with gloss finish wraps, it’s crucial to understand their nature and how they differ from other types of wrapping materials. These wraps are designed to offer a sleek, polished look, enhancing the aesthetics of various surfaces, be it a car, furniture, or packaging. However, a key practical consideration is their irreversibility once applied. Unlike matte finishes that can be easily corrected or removed, gloss finish wraps are permanent and intended for long-lasting display.

For best results with gloss wraps, professionals suggest preparation and planning. Ensure the surface is clean, smooth, and free from debris to achieve optimal adhesion. Using high-quality finishes tailored for vehicle wraps or other specific applications can significantly impact the final outcome, ensuring longevity and vibrancy of the wrap. Additionally, working in a controlled environment protects the wrap from accidental damage during application, as these delicate high-gloss surfaces are susceptible to fingerprints and smudges.

In conclusion, gloss finish wraps offer a sleek and modern aesthetic, but understanding their adhesion properties is crucial. While some gloss finish wraps are designed for permanent bonding, many are, in fact, reversible, making them a versatile choice for various applications. By considering the materials, knowing the nature of the finish’s adhesion, and implementing practical tips, you can effectively work with these wraps to achieve stunning results. Remember that choosing the right gloss finish wrap for your project depends on your specific needs and desired outcome, ensuring a successful and visually appealing transformation.